Our Electrically Insulated Multi-Pin Wire Terminal Push-In Connector represents a significant leap forward in electrical connection technology. Engineered for professionals who demand efficiency, reliability, and safety, this connector is designed to simplify complex wiring tasks across numerous industries. It integrates multiple conductive terminals within a single, robust housing made of high-grade, flame-retardant insulating material. The core innovation lies in its push-in termination mechanism, which allows for rapid, tool-free wire insertion. Each terminal is designed to accommodate a specific range of solid or stranded wire gauges, creating a gas-tight, vibration-resistant connection. Pre-assembled with locking clips and sealing plugs where applicable, this connector is the ideal solution for creating secure, multi-circuit connections in control panels, machinery, automotive systems, and outdoor lighting applications, drastically reducing installation time and minimizing human error.

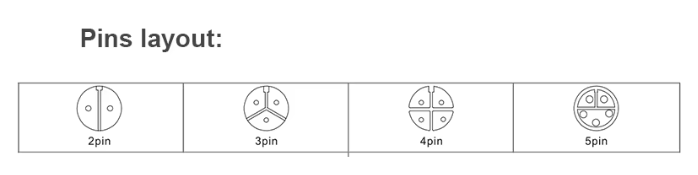

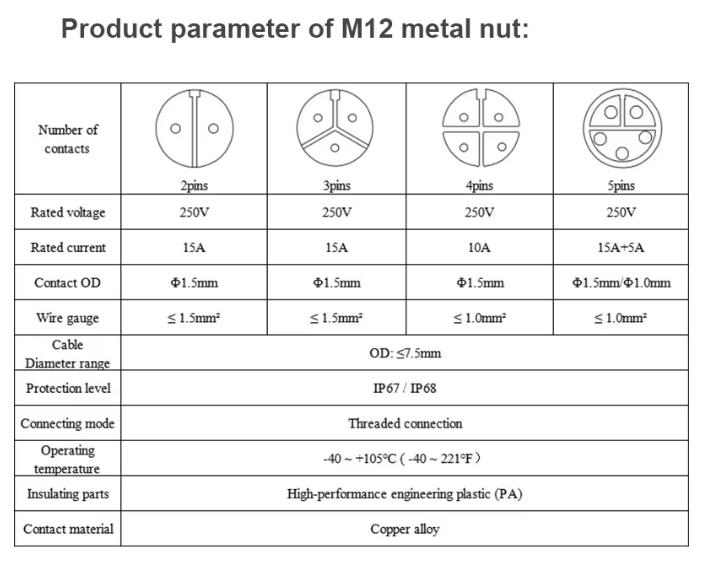

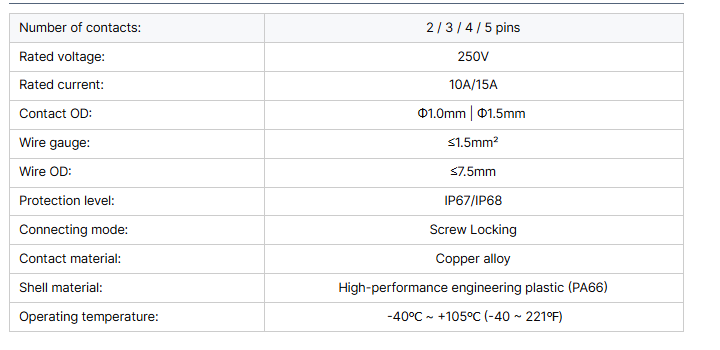

Multi-Pin Configuration: Available in 2 to 12+ pin variants, enabling the simultaneous connection of multiple circuits within a single, compact unit.

Push-In Wire Termination: The revolutionary spring-loaded cage clamp system allows for direct wire insertion without tools. A simple release lever is used for quick wire disconnection when needed.

Fully Insulated Housing: Constructed from premium polyamide (PA66) or similar thermoplastic, offering excellent flame retardancy (UL94 V-0 rated), high impact resistance, and protection against dust, moisture, and chemical corrosion.

Secure Locking Mechanism: An integrated locking clip ensures a positive and audible "click" when mated with a corresponding header, preventing accidental disconnection due to vibration or movement.

Polarized Design: The housing features a unique, asymmetrical shape that guarantees correct mating orientation, preventing misalignment and potential damage to the pins.

Wide Operating Temperature Range: Engineered to perform reliably in harsh environments, with a stable temperature range from -40°C to +105°C.

Clear Pin Numbering: Molded-in pin numbers facilitate easy and error-free circuit identification and troubleshooting during installation and maintenance.

Drastic Reduction in Installation Time: The tool-less push-in technology can reduce wiring time by up to 70% compared to traditional screw terminal or soldering methods, leading to lower labor costs and faster project completion.

Enhanced Connection Reliability: The constant, high-pressure contact force of the spring cage ensures a stable, gas-tight connection that is highly resistant to loosening under vibration, a common failure point in industrial and automotive settings.

Uncompromised Safety: The fully insulated housing prevents accidental contact with live terminals, protecting personnel from electric shock. The flame-retardant material adds a critical layer of safety in case of electrical faults.

Superior Durability in Demanding Conditions: With a high IP (Ingress Protection) rating, such as IP67, these connectors are protected against dust ingress and temporary immersion, making them perfect for outdoor, marine, and washdown environments.

Space Optimization: By consolidating multiple wire connections into one compact housing, these connectors help in designing more organized and space-efficient control cabinets and electronic assemblies.

Minimal Maintenance Requirements: The robust design and corrosion-resistant materials ensure a long service life with virtually zero maintenance, reducing the total cost of ownership.

The versatility and robustness of our Push-In Connectors make them indispensable in a wide array of sectors:

Industrial Automation & Control Panels: For connecting PLCs, sensors, actuators, and motor drives within factory automation systems.

LED Lighting Systems: Ideal for outdoor and architectural LED lighting, signage, and display screens where waterproof and vibration-proof connections are crucial.

Automotive & Transportation Electronics: Used in vehicle wiring harnesses for infotainment systems, lighting controls, and sensors in cars, trucks, and buses.

Renewable Energy: Connecting sensors and control units in solar power inverters and wind turbine monitoring systems.

Telecommunications & Network Equipment: Providing reliable interconnections in base stations, servers, and data communication racks.

Medical Equipment: Ensuring safe and dependable connections in diagnostic and patient monitoring devices.

Marine Electronics: Resisting corrosion and moisture in navigation and communication systems on boats and ships.

Q1: What wire types and sizes are compatible with this push-in connector?

A: Our connectors are designed to accept a wide range of solid and finely-stranded copper wires. The most common compatible wire gauges are between 20 AWG and 12 AWG. Please refer to the specific product datasheet for the exact specifications of each model.

Q2: Is a special tool required for wire insertion and release?

A: For insertion, no tool is required; wires can be pushed directly into the terminal. For release, a standard small flat-head screwdriver or a dedicated release tool is inserted into the release lever adjacent to each terminal to disengage the spring mechanism and withdraw the wire.

Q3: What is the IP rating of these connectors, and are they truly waterproof?

A: Many of our models are rated IP67, which means they are dust-tight and can withstand immersion in water up to 1 meter for 30 minutes. This makes them "waterproof" for most outdoor and industrial applications. Be sure to check the specific product code for its exact IP rating.

Q4: Can these connectors be used in high-vibration environments?

A: Absolutely. The push-in spring cage clamp maintains a constant pressure on the wire, creating a connection that is significantly more resistant to vibration-induced loosening than traditional screw terminals. The secure locking mechanism between the plug and header provides additional stability.

Q5: Are these connectors reusable?

A: Yes, they are designed for multiple mating and unmating cycles. The spring mechanism is tested for thousands of operations, and wires can be easily inserted and released as needed for circuit modifications or troubleshooting.

Contact person: Mr. Bei

Mobile phone: +86 13378428166

whatsApp: +86 13378428166

Address:2F, Bldg B, Guancheng High-Tech Industrial Park,

No. 2, Xiguangyue 1st Road, Xinhu Street,

Guangming District, Shenzhen, 518107

Copyright © 2025 Shenzhen Jiayunkang Technology Co., Ltd. All Rights Reserved. support: huaqi

This website uses cookies to ensure you get the best experience on our website.