Product Description

The M15 Module Series represents the next generation of waterproof connectivity solutions engineered for extreme environmental conditions. This innovative connector system combines military-grade protection with modular flexibility, offering unparalleled performance in the most demanding applications. Featuring a unique multi-port modular design, the M15 series allows for customized configuration of power, signal, and data transmission within a single compact housing. With an IP68/IP69K protection rating, these connectors withstand high-pressure washdowns, prolonged submersion, and exposure to corrosive chemicals. The advanced dielectric materials and precision-engineered contacts ensure optimal electrical performance while the robust stainless steel coupling mechanism provides reliable mating under vibration and mechanical stress.

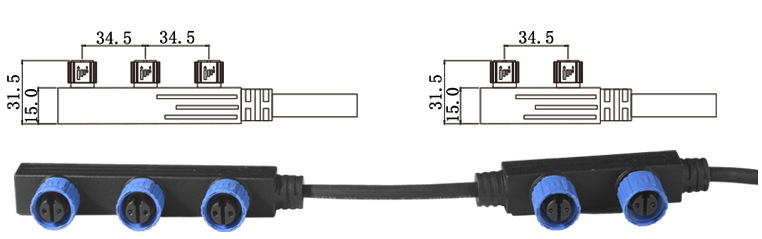

Product parameters

Product model: M15 module series without male head

Number of cores :2/3 pin

Shell material: Nylon (PA)

Rated voltage :250V

Rated current :10A

Waterproof rating :IP67/68

Operating temperature :-40° C ±105 ° C

Cable diameter :OD≤ 8.2mm

Connection method: Threaded connection

Product Features

Advanced Modular Design

The M15 series features a revolutionary modular configuration system that allows combining power contacts (up to 16A), signal contacts, and coaxial/RJ45 modules within a single connector body. This flexibility enables customized solutions for complex interconnection requirements.

Military-Grade Environmental Protection

Achieving both IP68 and IP69K ratings, the connector withstands prolonged submersion, high-pressure jet cleaning (1450 psi at 80°C), and exposure to aggressive chemicals, making it suitable for food processing, marine, and military applications.

Enhanced Electrical Performance

Gold-plated beryllium copper contacts ensure low contact resistance (<2mΩ) and stable electrical characteristics. The optimized contact geometry provides superior mating reliability and signal integrity.

Robust Mechanical Construction

Stainless steel coupling mechanism with triple-start threading enables quick mating (¼ turn locking) while providing exceptional resistance to vibration and mechanical shock. The housing utilizes glass-filled thermoplastics with UV stabilization.

Thermal Management

Advanced thermal compound design allows efficient heat dissipation, maintaining stable performance in high-current applications and extreme temperature environments.

Visual Status Indicators

Optional integrated LED status indicators provide visual confirmation of connection status and power availability, enhancing system maintenance and troubleshooting.

Product Advantages

Space Optimization

The modular design reduces installation space requirements by up to 60% compared to using multiple individual connectors, while simplifying cable management and system design.

Lifecycle Cost Reduction

Exceptional durability and reliability significantly reduce maintenance requirements and replacement costs. The 500+ mating cycle rating ensures long-term performance in frequently connected applications.

Installation Efficiency

The quick-lock coupling system reduces installation time by 70% compared to traditional Threaded Connectors. Color-coded modules and intuitive keying prevent mating errors.

Future-Proof Design

Modular architecture allows for field upgrades and configuration changes without replacing the entire connector system, protecting your investment against future technology changes.

Cross-Industry Compatibility

Meets multiple international standards including UL, CSA, CE, and RoHS, ensuring global acceptance and compatibility across various industrial sectors.

Application Fields

Heavy Industrial Equipment

Mining machinery and drilling equipment

Construction and agricultural machinery

Offshore drilling platforms

Hydraulic control systems

Transportation Infrastructure

Railway signaling and control systems

Electric vehicle charging infrastructure

Airport ground support equipment

Marine navigation and control systems

Energy Sector Applications

Wind turbine control systems

Solar power generation equipment

Nuclear plant monitoring systems

Oil and gas exploration equipment

Specialized Environments

Food and beverage processing machinery

Pharmaceutical manufacturing equipment

Military and defense systems

Emergency response equipment

Building Technology

Smart building management systems

Elevator and escalator controls

Security and surveillance systems

Data center infrastructure

Frequently Asked Questions (FAQ)

Q1: What makes the M15 series suitable for high-pressure washdown environments?

A: The IP69K rating certifies protection against high-pressure, high-temperature steam cleaning (1450 psi at 80°C), with specialized sealing materials that resist degradation from cleaning chemicals.

Q2: Can different module types be combined in one connector?

A: Yes, the modular design allows mixing power, signal, data, and coaxial modules in any configuration within the same connector body, providing maximum design flexibility.

Q3: How does the quick-lock mechanism work under vibration?

A: The triple-start thread design with positive locking mechanism ensures vibration resistance up to 100m/s², maintaining secure connections in the most demanding environments.

Q4: What is the expected service life in harsh environments?

A: The combination of corrosion-resistant materials, robust construction, and high-quality seals ensures a minimum service life of 10 years in harsh industrial environments.

Q5: Are custom configurations available?

A: Yes, we offer complete customization including contact arrangements, shell sizes, and special materials to meet specific application requirements.

Q6: How does the thermal management system work?

A: Advanced thermal interface materials and optimized contact spacing allow efficient heat dissipation, preventing overheating in high-current applications.

Contact person: Mr. Bei

Mobile phone: +86 13378428166

whatsApp: +86 13378428166

Address:2F, Bldg B, Guancheng High-Tech Industrial Park,

No. 2, Xiguangyue 1st Road, Xinhu Street,

Guangming District, Shenzhen, 518107

Copyright © 2025 Shenzhen Jiayunkang Technology Co., Ltd. All Rights Reserved. support: huaqi

This website uses cookies to ensure you get the best experience on our website.